The future is built on wood

Corporate development (Continue) writing success stories

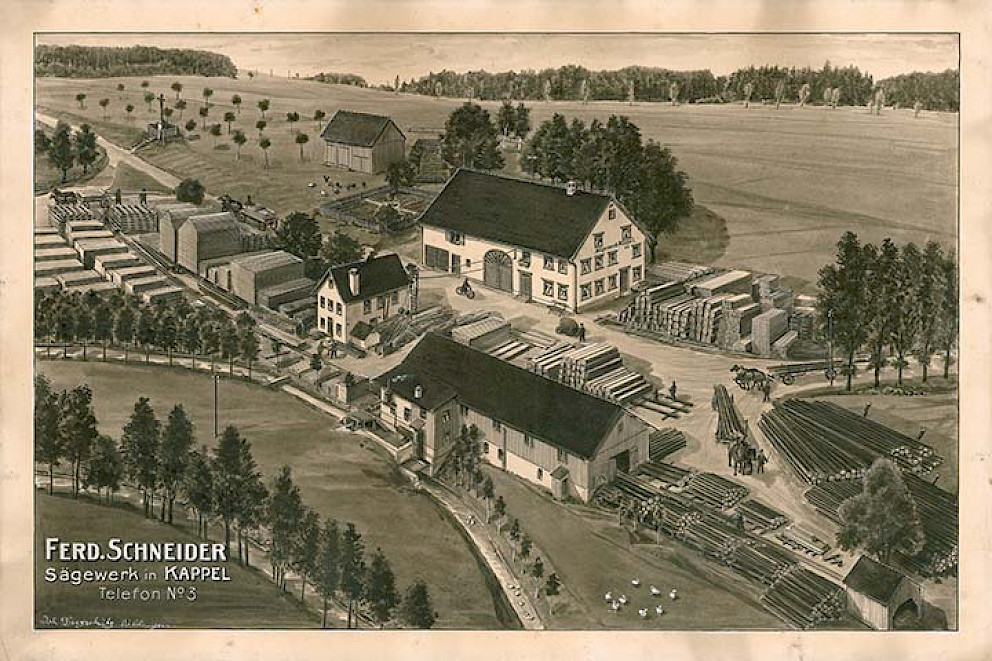

The beginnings were in Eberhardzell, more precisely in Kappel in 1911. This is where the master carpenter Ferdinand Schneider founded the Schneider sawmill. Only the view is picturesque here, because from the very first hour, work was carried out continuously with wood and on the future of the company. 110 years later, around 500 employees at three locations are working for environmentally friendly building materials made of wood.

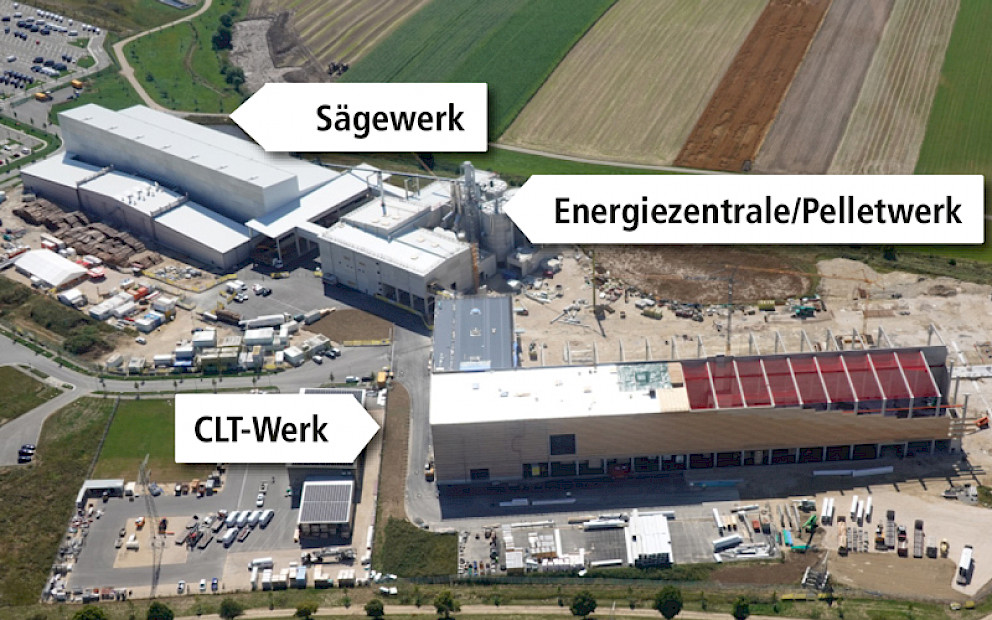

The expansion Our new location in Messkirch (Germany)

Quality, customer orientation and, above all, environmentally friendly building materials are becoming increasingly popular - and our timber plant is growing with it. For this to succeed, we need space, which we have found at our new location in Messkirch. In the Nördlicher Bodensee industrial park, we are investing a total of 100 million euros on an area of eight hectares. The result is production with a closed value chain, as has already proven itself in Eberhardzell.

Milestones in our history

That best wood SCHNEIDER is where it is today is no coincidence. Numerous milestones mark the path to today's success, which you can discover here.

Good for nature, good for us all. Tested, certified.

PEFC is a transparent and independent system for ensuring sustainable forest management and thus a global "forest MOT". Forest certification according to PEFC standards is based on very strict guidelines for the sustainable management of forests. This management is controlled by competent and independent organisations.

An EPD (Environmental Product Declaration) presents the life cycle of a building product as well as information relevant to building physics and in general. The Environmental Product Declaration is drawn up in accordance with the DIN EN 15804 standard and thus ensures a uniform assessment and comparability of EPDs.

Material guarantee deposited with the Central Association of the German Roofing Trade. Only the professional processing of flawless materials guarantees true customer satisfaction. This is why the ZVDH has developed the material guarantees together with renowned partners in the roofing industry. We offer the guild companies protection in the event of material complaints, in that we, as the manufacturer, have deposited a comprehensive guarantee for our products.